How did the Variable Frequency Drive(VFD) Develop ?

VFDs are used to allow an AC motor to operate at any wanted speed by altering the frequency supplied to them. Medium-voltage drives begin to work up to 15,000 V and can reach 20,000 HP or more. Low-voltage drives are designed to operate below about 690 V with a maximum of about 1,000 HP.

Hammond says that, in the ’70s when drives started using widely , people began to notice the bad after-effect. Cables and transformers were over-heating, and utility customers complained of interference with TVs, telephones, and instrumentation. The Institute of Electrical and Electronics Engineers (IEEE) established the standard 519 in 1981; it was voluntary until 1992. The standard required that harmonic distortion of the current draw by a facility must be less than 5%, he explains. After the standard became mandatory in 1992, many facilities started having to spend money to comply with standard 519. Robicon’s solution shakes the market in 1994.At the time VFDs were being used with centrifugal pumps or fan loads to save energy, but they were injecting harmonic currents into supply lines. They were also reducing the life expectancy of the motors they were driving. Hammond and his fellow engineers at Robicon saw there was a market and business opportunity for medium-voltage VFDs.

Thus what have Hammond and Robicon done? instead of connecting semiconductor switches in series to achieve higher voltages,Hammond saw that , it is very difficult, it would not be difficult to link complete low-voltage converters (known as power cells) in series. Each phase of the motor could be driven by several power cells connected in series. (A power cell, as used by Robicon/Siemens, is a specific type of converter that takes in three-phase AC power at fixed frequency and voltage and delivers single-phase AC power at variable frequency and voltage.)

Hammond asked that, “What about we control the power cells to switch one at a time in a multi-level topology?” By stacking low-voltage power cells in series, “we can go as high as six cells in each phase, to 7,200 volts. We can vary the number of cells according to the voltage needed.”

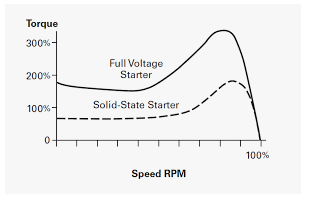

Voltage fed to the motor is improved by switching cells at different times. “This gave us much benefits, Hammond says. Switching cells reduces stress on the motor and produces smoother torque at different times . In addition, a transformer powers to all the cells and cancels many harmonics in the VFD feeds so that they are not injected into the plant’s power supply. he explains. The new drive is in harmony with its environment at both the input and the output ,

The result of VFDs’ development was called the Perfect Harmony, the first practical multi-level drive. And the current existing motors didn’t need to be replaced with the new drive, the reason is that the currents flowing into the motor are so smooth and the extra losses are avoided .

The first Perfect Harmony was controlled by a 16-bit microprocessor, however it was so slow that high-speed control functions required dedicated hardware. A few years later When Intel came out with the Pentium , Hammond says, they upgraded to an all-digital control package using the Pentium, shrinking the control package to the size of a large book. With all controlled functions in software, the complex controlling strategies became into reality, he says.

Hammond says that it took a year to build the prototype, and in 1994 when the first drives became available on the market, they sold 47 units. And then Robicon’s patent was issued in 1997.

Robicon’s second customer was an oil and gas company who bought 21 of the first 47 Perfect Harmony drives for an offshore platform, Hammond says. Originally The company had ordered low-voltage VFDs, when the engineer began to approve them and saw the Perfect Harmony prototype, and then he replace the order to Perfect Harmony drives. Because he thought that the drives were for submersible pumps in wells which were under the sea, and it cost $1 million to replace if they fail to succeed. Using Perfect Harmony drives would avoid taking such risk of failure, Hammond explains.

The Perfect Harmony has a significant feature—the cell bypass option—Hammond says. This feature takes advantage of the inherent redundancy in owing multiple cells. The cell bypass option provides a contactor for each cell to remove it from the string if it fails. Then the drive can continue to operate with the remaining cells. Even though the maximum output voltage is reduced, but the customer can continue to operate the equipment.

Variable Frequency Drive Operating Principle:

Another oil company required and was guaranteed that their drives would run without interruption for five years. Hammond explains that some processes take much time to stabilize after start-up, so the company wanted a drive that would never cause a shutdown. The drives provided have realized the five-year goal.

Hammond reports that there are international competitors, particularly in China, where many companies have copied the Perfect Harmony market. Hammond says.“We were naive and only applied for US patents,” Siemens expects competition to rise when the US patent expires.

Siemens is manufacturing Perfect Harmony VFDs at its main plant in Pittsburg, other plants in Germany, Shanghai, and Brazil. Approximately 13,000 drives have been installed worldwide, and total sales are approaching $2 billion. “It’s been an interesting time,” says Hammond.

Siemens celebrated the 20th anniversary of Hammond’s invention of Perfect Harmony on August 8, 2015.

Return: Back to Previous Level

HOT SALE

-

TRS80 series soft starters with integrated bypass can greatly reduce the construction cost in its application. TRS80 is compact, easy to operate soft starter, designed for use with standard 3-phase motors. It provides an advanced method of reducing current during motor starting and stopping. TRS80 s...